What is a G Clamp?

Tork G Clamp delivers unbeatable clamping strength for ducts and construction. Crafted for quick assembly and enduring grip, this clamp guarantees consistent performance. Especially prominent in ventilation and building sectors, its high-quality design speaks to TORK's commitment to excellence.

The G clamp is a valuable tool designed to hold objects tightly together to prevent movement or separation during work. Originating from its “G” shape, this clamp provides a distinct advantage over other types, thanks to its unique design and functionality. By understanding the basic mechanics, users can ensure optimal application while ensuring they adhere to all g clamp safety precautions.

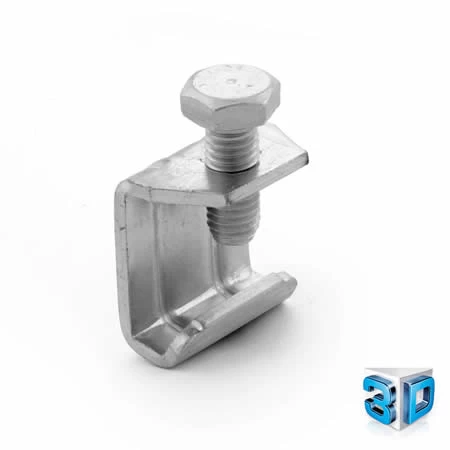

Click to view the product in 3D

Click to view the product in 3D

Tork G Clamp delivers unbeatable clamping strength for ducts and construction. Crafted for quick assembly and enduring grip, this clamp guarantees consistent performance. Especially prominent in ventilation and building sectors, its high-quality design speaks to TORK's commitment to excellence.

The G clamp is a valuable tool designed to hold objects tightly together to prevent movement or separation during work. Originating from its “G” shape, this clamp provides a distinct advantage over other types, thanks to its unique design and functionality. By understanding the basic mechanics, users can ensure optimal application while ensuring they adhere to all g clamp safety precautions.

Key Features of the G Clamp

Delving deeper into the G clamp, its features set it apart, ensuring both longevity and effective performance.

High-Strength Design for Maximum Hold

The G clamp ensures a robust grip that's crucial for tasks demanding utmost precision. Its sturdy build guarantees that the clamped objects remain firmly in place, preventing any unexpected shifts or movements.

Swift and Effortless Assembly

Time is often of the essence in projects, and with the G clamp, users can set it up quickly without fumbling around. The design intuitively guides users, making the assembly process both smooth and rapid.

Durable 5-8 Micron Coating

The coating enhances the clamp's resistance to wear, tear, and corrosion, ensuring it remains functional even after prolonged usage. It's a testament to the clamp's durability, assuring users of a product that can withstand the test of time.

Materials

-DIN EN 10111: Hot Rolled Low Carbon Steel

The G clamp's primary material is hot-rolled low carbon steel, compliant with the DIN EN 10111 standard.

-ISO 898-1: Premium Carbon Steel Alloy

Further enhancing its strength is the incorporation of a premium carbon steel alloy, conforming to the ISO 898-1 standard.

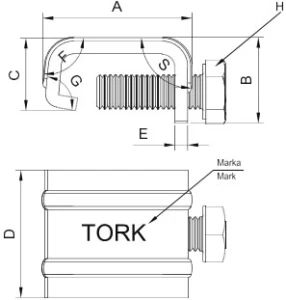

Dimensions

Screw (H) Dimension |

A (±1) |

B (±1) |

C (±1) |

D |

E |

S (±5) |

F (±5) |

G (±5) |

Alkalic coverage (average micron) |

Corrosion Resistance Average |

M8 x 20 |

30 |

18,5 |

13 |

27 |

2,5 |

90° |

95° |

100° |

Min. 5 |

White Min.72 h |

M8 x 25 |

34,5 |

20 |

17,5 |

30 |

3 |

92° |

93,5° |

103,6° |

Diverse Applications of G Clamp

Given its sturdy build and dependable clamping strength, it’s no surprise that g clamps find use in various sectors. One of the primary g clamp uses is within ventilation systems. When considering g clamp vs c clamp, the G clamp's tailored design for the flange profiles of air ducts often makes it the preferred choice.

The G clamp is also an invaluable tool in the building and construction sector. Its adjustable g clamp feature allows users to tailor the grip according to the specific requirements. Additionally, when examining the g clamp parts, its robust build is a testament to its longevity and reliability in construction scenarios.

Why Choose Tork G Clamp?

As the market overflows with various clamping solutions, Tork’s G-Clamp distinguishes itself through a blend of robustness, innovation, and reliability.

Broad Utility Across Sectors

A common question posed by many is the g clamp use across various domains. From ventilation to the expansive world of construction, Tork’s G Clamp offers unparalleled versatility. Its adjustability, a feature stemming from the adjustable g clamp mechanism, allows for its application across various tasks, materials, and conditions.

Quality Assurance with Every Clamp

Tork's reputation in the clamping industry is not merely due to the products they offer but the assurance accompanying them. Professionals can proceed with their tasks, knowing that behind every Tork G Clamp is a legacy of quality and innovation.

What is a G Clamp? Dimensions