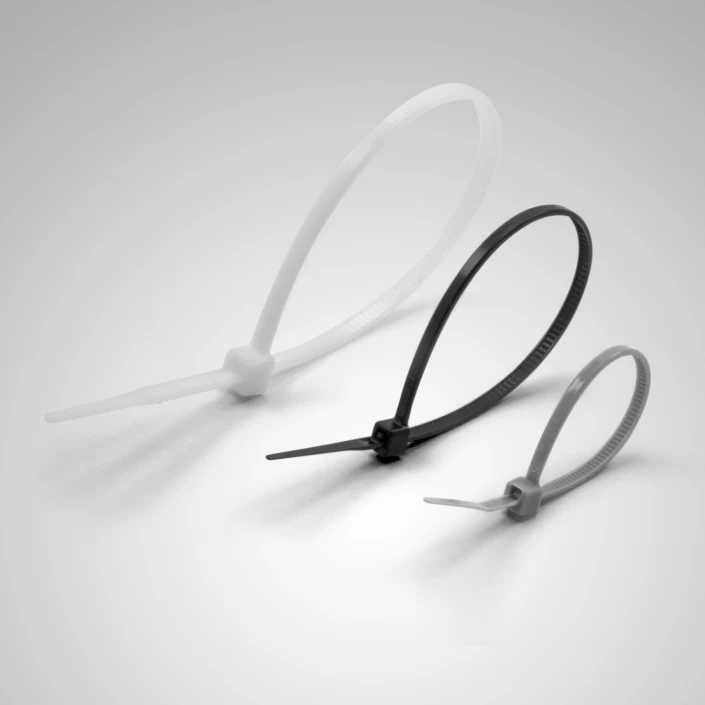

UV Resistant Cable Ties

- Excellent resistance to UV rays

- Suitable for photovoltaic applications

- High tensile strength with low application force

- Edge surface slope for easy application

- Easy application manually or with apparatus

Click to view the product in 3D

Click to view the product in 3D

Uv resistant Tork cable ties are produced from extra-doped polyamide 6.6 material that provides extra resistance against UV rays. UV resistant Torque cable ties tested according to CEI EN 62275 norm simulate a condition equivalent to at least 10 years of exposure to sunlight in southern European countries.

Key Features of UV Resistant Cable Ties

UV Resistant Cable Ties from Tork Clamps are engineered to offer superior performance and durability in various applications, especially where exposure to ultraviolet (UV) light is a concern. Here are the key features that set these cable ties apart:

- High-Quality Material Composition

Polyamide 6.6: The UV resistant cable ties are made from Polyamide 6.6, a type of nylon known for its excellent mechanical properties, including high tensile strength, rigidity, and thermal stability. This material ensures that the cable ties can withstand harsh environmental conditions without degrading.

- Optimal Moisture Absorption

Moisture Absorption Rate of 2.7% at 50% Relative Humidity: The UV resistant cable ties maintain their integrity and mechanical properties even in environments with varying humidity levels. The low moisture absorption rate minimizes the risk of corrosion under the tie and ensures consistent performance.

- Wide Range of Operating Temperatures

Working Temperature Range: The UV resistant cable ties are designed to operate effectively in a wide temperature range, from -40 °C to +85 °C. This feature ensures that they remain functional and durable in extreme cold and heat, making them suitable for various climatic conditions.

Application Temperature Range: With an application temperature range of -10 °C to +60 °C, these cable ties can be applied in a broad spectrum of environments, ensuring flexibility and reliability in their use.

- Combustion Degree and Safety Standards

UL 94 Class V2 Combustion Degree: This classification indicates that the cable ties are flame retardant, with a burning stop time within 30 seconds on a vertical specimen; drips of flaming particles are allowed. This feature is crucial for applications where fire safety is a priority.

- Halogen-Free Certification

Halogen-Free: Being halogen-free means that these cable ties do not release toxic gases when exposed to fire, making them safer for both users and the environment. This characteristic is particularly important in enclosed spaces or in industries where safety and environmental regulations are stringent.

Benefits of Using UV Resistant Cable Ties

UV Resistant Cable Ties offer a range of advantages that make them a preferred choice for securing cables and wires in various settings, particularly those exposed to the outdoors and harsh environmental conditions. Here are the key benefits of using these cable ties:

- Enhanced Durability and Longevity

Resistance to UV Radiation: The primary benefit of UV resistant cable ties is their ability to withstand prolonged exposure to ultraviolet light without degrading. This resistance ensures that the ties maintain their strength and flexibility over time, reducing the need for frequent replacements and offering long-term reliability.

- Safety and Compliance

Flame Retardant Properties: The UL 94 class V2 rating signifies that these cable ties are flame retardant, adding an extra layer of safety in environments where fire risk is a concern. This feature is crucial for maintaining safety standards in industrial and commercial settings.

UV Resistant Cable Ties Technical Specifications

•Raw material: Polyamide 6.6

• Moisture Absorption: 2.7%

•(50% relative humidity)

• Working temperature: -40 ° C + 85 ° C

• Application temperature: -10 ° C + 60 ° C

• Combustion degree: UL 94 class V2

• Halogen free: Yes

UV Resistant Cable Ties Application Areas

- Photovoltaic areas

- Outdoor applications

- Industrial cabling

- Energy sector

UV Resistant Cable Ties Certifications

UV Resistant Cable Ties Box Content

| Size | ||||||||

| Product Code | Length (L) | Width (B) | Strip Thickness (A) | Colour | Tighten Range | Max Tensile Strength | Quantity In a Nylon Bag | Quantity l Carton Bo |

| mm | mm | mm | max mm | Kg/f | ||||

| TRK-100-25W | 100 | 2.5 | 1.0 | White | 22 | 8 | 100 | 26.000 |

| TRK-150-25W | 150 | 2.5 | 1.0 | White | 35 | 8 | 100 | 20.000 |

| TRK-200-25W | 200 | 2.5 | 1.0 | White | 50 | 8 | 100 | 18.000 |

| TRK-140-35W | 140 | 3.5 | 1.2 | White | 31 | 18 | 100 | 12.000 |

| TRK-200-35W | 200 | 3.5 | 1.2 | White | 50 | 18 | 100 | 10.000 |

| TRK-250-35W | 250 | 3.5 | 1.2 | White | 65 | 18 | 100 | 8.000 |

| TRK-280-35W | 280 | 3.5 | 1.2 | White | 74 | 18 | 100 | 8.000 |

| TRK-370-35W | 370 | 3.5 | 1.2 | White | 98 | 18 | 100 | 6.000 |

| TRK-200-45W | 200 | 4.5 | 1.3 | White | 50 | 22 | 100 | 7.000 |

| TRK-250-45W | 250 | 4.5 | 1.3 | White | 65 | 22 | 100 | 6.000 |

| TRK-300-45W | 300 | 4.5 | 1.3 | White | 80 | 22 | 100 | 5.000 |

| TRK-370-45W | 370 | 4.5 | 1.3 | White | 98 | 22 | 100 | 4.000 |

| TRK-430-45W | 430 | 4.5 | 1.3 | White | 120 | 22 | 100 | 3.000 |

| TRK-300-75W | 300 | 7.5 | 1.5 | White | 75 | 55 | 100 | 3.000 |

| TRK-370-75W | 370 | 7.5 | 1.5 | White | 98 | 55 | 100 | 2.500 |

| TRK-450-75W | 450 | 7.5 | 1.5 | White | 120 | 55 | 100 | 2.000 |

| TRK-550-75W | 550 | 7.5 | 1.5 | White | 155 | 55 | 100 | 1.500 |

| TRK-750-75W | 750 | 7.5 | 1.5 | White | 220 | 55 | 100 | 1,200 |

| TRK-600-90W | 600 | 9.0 | 1.6 | White | 165 | 80 | 100 | 1.200 |

| TRK-710-90W | 710 | 9.0 | 1.6 | White | 205 | 80 | 100 | 1.200 |

| TRK-760-90W | 760 | 9.0 | 1.6 | White | 220 | 80 | 100 | 1.200 |

| TRK-900-90W | 900 | 9.0 | 1.6 | White | 260 | 80 | 100 | 1.200 |

| TRK-1200-90W | 1200 | 9.0 | 1.6 | White | 370 | 80 | 100 | 1.200 |