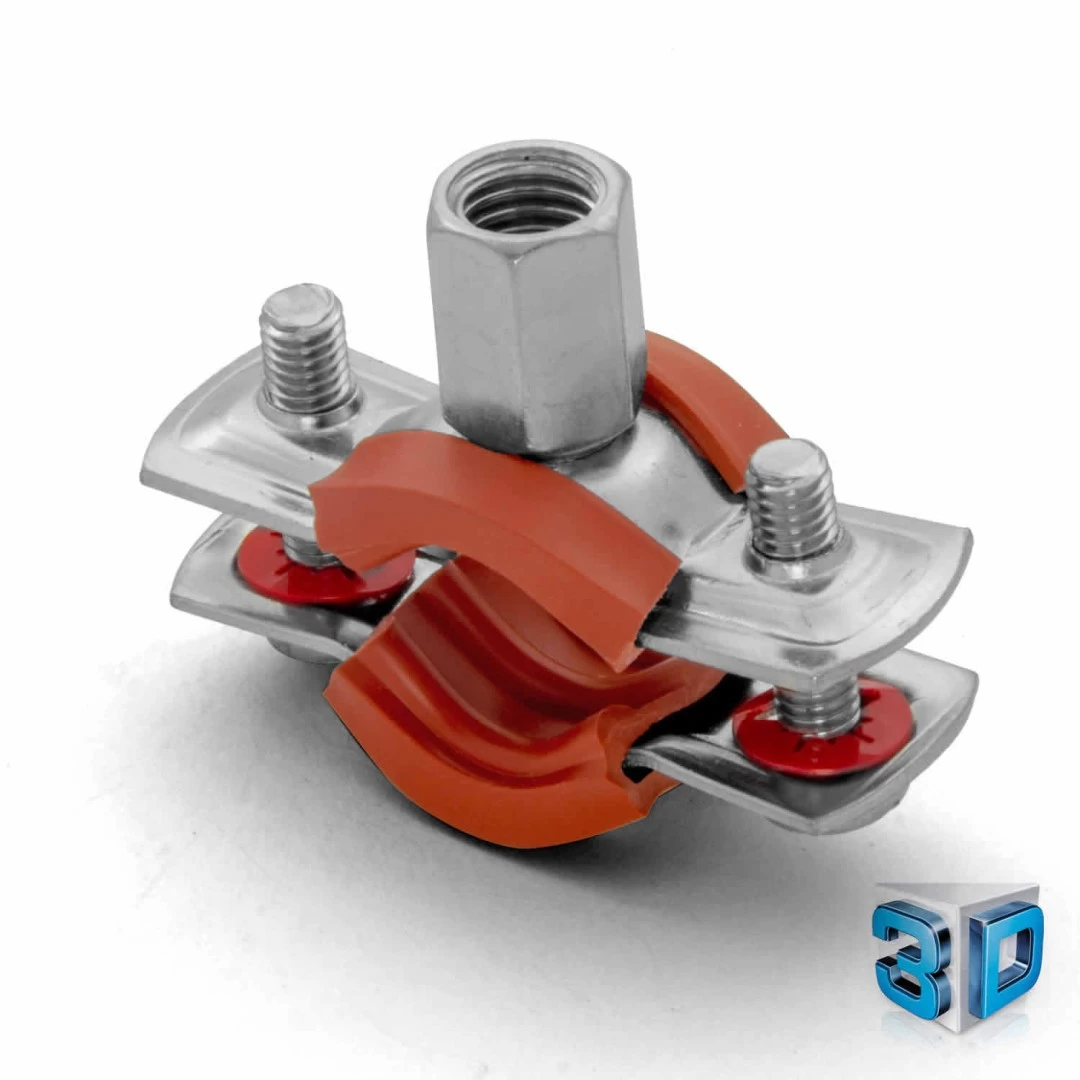

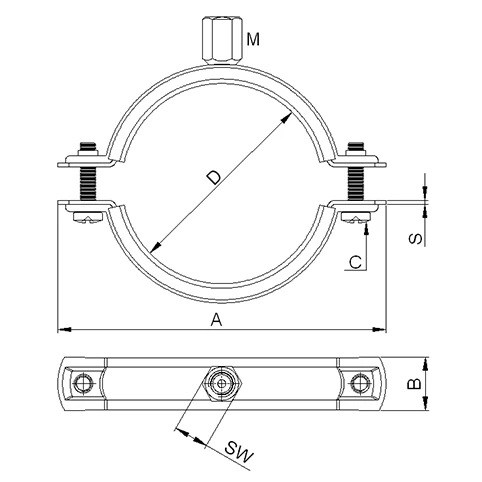

DG5 Pipe Clamps With Combi Nut And Rubber

1 – Rubber profile with double locking screw and low PAH content ZEK 01.04-08, category 2

2 – High strength and breaking load values on slopes, designed with your safety in mind.

3 – Time-saving, easy and fast assembly features

4 – Low values in hazardous PAH chemicals – protects people and the environment.

5 – The plastic washer attached to the Locking Screw prevents the screw from being lost.

6 – Zinc (Cr + 3) coated. (min. 5-10µm)

7 – Sound insulation complies with DIN 4109.

8 – EPDM rubber is used for sound insulation.

9 – Profile temperature resistance is between -50˚C and 110˚C.

10 – Profile hardness is Shore (A) 50 ± 5

Click to view the product in 3D

Click to view the product in 3D

- Pipe clamps or pipe fixings are best described as a support mechanism for suspended pipes, either horizontal top or vertical adjacent to a surface.

- They are vital to ensure that all pipes are securely fixed and also allow any pipe movement or expansion that may occur.

- Pipe fixing failure can cause significant and costly damage to a building so it is important to do it correctly.

- Standard clamps are typically secured using two screws, one on each side of the clamp. They can be with or without a primer depending on the application.

- Standard clamps work by fixing two screws, one on each side of the clamp. Red washers are placed to prevent screws from slipping during the assembly process.

Technical Specifications and Performance Standards

Ensuring the stability and longevity of pipe installations, the DG5 Pipe Clamp is a pinnacle of engineering precision. It is designed to be a dependable support for piping systems, providing a secure grip that accommodates both horizontal and vertical setups. The robust design guarantees that pipes remain immobile, safeguarding infrastructure from the damages of unanticipated pipe movements or failures. The dual locking screw mechanism is a testament to the clamp's reliability, engineered to uphold the integrity of pipe systems even in the most demanding situations.

Material Specifications and Coating Details

Crafted from premium materials, the DG5 Pipe Clamp is distinguished by its high-quality rubber profile that is fortified with a zinc-based coating for enhanced protection against corrosion. This specialized coating is meticulously administered to ensure a consistent layer that stands up against environmental challenges, securing a longer lifespan for the clamp. The combination of a resilient rubber profile and a steadfast zinc coating contributes to the clamp's overall strength, making it a trusted choice for securing piping systems.

Temperature Resistance and Profile Hardness

The DG5 Pipe Clamp is engineered to withstand substantial temperature fluctuations, affirming its reliability in various climatic conditions. Its construction material is rigorously tested to endure temperatures ranging from the chill of minus fifty degrees Celsius to the intensity of one hundred and ten degrees Celsius. This impressive temperature resilience is complemented by a Shore (A) hardness rating that epitomizes the clamp's balanced approach to flexibility and rigidity, enabling it to absorb and dissipate energy without losing its structural integrity.